Chemical Component Index of Diatomaceous Earth Filter Aid

applied range |

flitration products |

petroleum product |

oil assitive, detergent addictive, dispersant addictive, cutting oil, coal tar, journal-box oil, burning oil, lubricating oil, waste lubricating oil, transformer oil, distillation oil remaining |

paint dyestuff product |

alkide resin, spirit tolu oil soap, expoxy resin, zapon, varnish, dope, dyestuff, tatanis sulfate fluid |

cellulose fluid product |

alkyd cellulose, methyl cellulose, artificial fagbric, sulfinic acid waste fluid, sodium thicyante fluid |

acid item |

sulphruic acid, hitric acid, phosphoric acid, ethlic acid, synanthrin acid, cresylic acid, surphur, digallic acid |

general chemical product |

acetone composite, styrene, alcohol, glycerol, aluminum sulfate fluid, calmogatrin flocculated sediment, diethanol amine, ethanediol, arsenite, vitriol, phosphate, tinkalite fluid, butyral dehyde, phenolics, dihy drophenarsazine, polytene, polysthylene glycol, polybutylene resin, silver chloride, silver iodide, rock salt, sodium silicate, rocket fluid flamming material, chlorinated hydrocarbon fluid. |

oil fat and wax product |

castor oil, coconut oil, palm oil, cotton seed oil, bean oil, corn oil, tall oil, tung oil, lated paint, oil-based paint, reclaimed rubber, agal-agal, |

fruit vegetable fluid |

lemon juice, apple juice, carrot juice, grape juice, orange juice, plum juice, tangerine juice, honey, vanilla |

drink and other brewing product |

beer, malt beverage, rice wine, yellow rice wine, whisky, brandy, vinegar, beansoy, grape wine, various fruit wine. |

medicine |

antibiotics, fluid nutrition, streptomycin, synthetic blood, vitamine, TCM fluid |

water disposition |

papermaking factory waste water, white water, oil well waste water, swimming pool water, lemin waste water, river water, lake water. |

sugar and syrup fluid |

glucose phosphate, glycolipid, fermented syrup, thin juice, |

other items |

fetterine, cleaning mixture, snow algin, urea, electrolyte, seaweed, electroplating mixture, soap suds. |

Filtration

General Considerations

Filtration is the separation of solids from liquids by forcing the liquid to flow through a porous medium and depositing the solids on the medium. A filter aid is a finely divided material which, when added to the liquor to be filtered, helps control flow and solids removal. The septum, usually screen or cloth, serves principally as a support for the cake. The filter aid forms a porous layer on the septum and thus the filter aid is the filtering medium that traps the solids being removed and prevents them from blinding the septum. Filter aid filtration is mechanical, not chemical in nature. Irregularly shaped particles interlace and overlay in a fashion that leaves 85 to 95 % voids or open spaces. These voids form billions of microscopically fine interstices between the filter aid particles. The size of these openings is so minute that the unwanted solids are strained from the liquid. The vast number of openings compensates for their small size resulting in fast flowrates and brilliant clarity.

Good filter aids are light in weight, chemically inert and form high porosity filter cakes to maintain free flow of the liquid. The structure of the particles must be such that they will not pack too closely. This not only permits high initial liquid flow but also provides pore spaces to trap and contain the filterable solids and leave a high percentage of channels remaining open for flow. Particle size distribution must be tailored to permit precoating on coarse wire and yet give the desired flow rate and clarity. Dicalite perlite, diatomite and cellulose filter aids meet these criteria. They are available in a variety of grades to suit the solids removal requirement of any application.

Pressure Filtration

General Operating Notes

The filter septum serves principally as the support for the filter aid cake. However, the effect of the septum on performance is sufficient to warrant careful selection. The size of the opening should be fine enough to retain the filter aid particles and allow a firm cake to be formed quickly while at the same time giving a minimum resistance to flow. The material must be able to withstand chemical, pressure and temperature conditions existing during filtration. The two most widely used septa are metal and cloth. The most common metal screen is 24 x 110 Dutch Weave. Addition of Dicacel will improve the precoatability of finer grades.

Precoat

In most cases, the first step is formation of the precoat. It is a thin layer, 1.5 to 3.0 mm (1/16 - 1/8 inch), which protects the septum and ensures clarity by stopping the solids at the surface. The filter aid grade used for precoat must be carefully selected to allow the fastest possible flow yet trap the solids. A slurry is made from filtered liquid, or sometimes water, and filter aid. The concentration should be low as possible, 0.5 % is typical. Agitation in the precoat tank should be sufficient to keep the filter aid in suspension. Excessive agitation for extended time may break down the particles. Filter aids should be added at 500 to 1200 g/m2 (10 - 25 lbs/100 ft2) of filter area. The precoat is formed by recirculating the filter aid slurry through the filter. The coarser particles deposit themselves first on the screen followed by smaller ones. Precoating rate of 40 litre/m2/min. (1 GPM/ft2) is normal. Much lower rates are used with higher viscosity liquids. There should be at least 0.07 kg/cm2 (1 psi) differential pressure during the precoat process. Precoating liquor should clear up within 10 to 15 minutes.

Bodyfeed

Addition of filter aid to the liquid to be filtered is referred to as bodyfeed. The type and grade as well as quantity to be added is vitally important to obtain the highest filtration flowrate consistent with the clarification required. Filter aid dosage varies with the solids content and other variables specific to each application. In general, a dosage of ? of the percent solids by weight is close. Bodyfeed can be added directly to the tank of liquid to be filtered, or dosed from a slurry tank into the filter inlet.

Grade Selection

Clarity is considered by many engineers to be the most important measure of efficiency in filter aid filtration. A high quality filter aid is most important for uniform results day after day. Selection of the particular type and grade of filter aid having the correct particle size and distribution is a major factor. After these come many considerations such as the quantity of filter aid to be used; flowrate needed to meet plant production schedules, equipment limitations and general filtration conditions. All of these can best be resolved by tests using the actual liquid involved.

Types of Pressure Filters

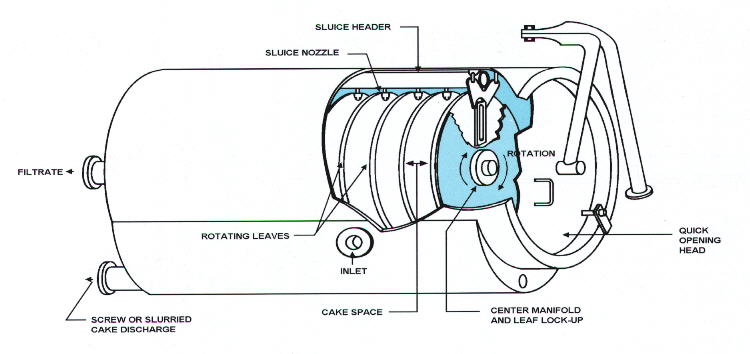

HORIZONTAL TANK-ROTATING LEAF

AUTOMATIC JET SPRAY CLEANING FILTER

The leaves in this filter rotate during cleaning but are stationary during filtration. For wet discharge, the leaves rotate past a sluice nozzle. For dry discharge, the cake is removed by vibrating the leaves or by rotating them past a scraper or a brush and the released cake is a screw conveyor.

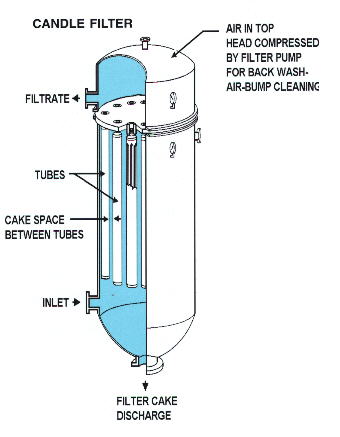

TUBE OR CANDLE FILTER

|

The tube filter is a vertical tank filter with tubes suspended from a tube sheet. Filter cake is formed on the outside of the tube and filtrate flows up through the tube into the head and out. The tubes are cleaned by high rate backwashing often assisted by a hydraulic "pump". |

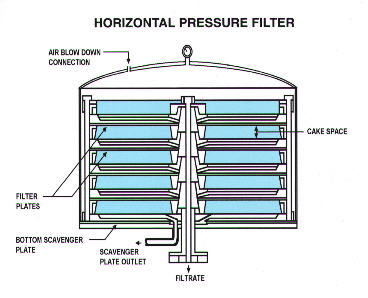

HORIZONTAL PRESSURE FILTER

|

Filtration takes place only from the top of the plate in this filter so that even with intermittent operation, the cake remains in place. In the filter shown, the leaf assembly is cleaned and dressed (usually with paper) outside of the filter. In other variations, the cake may be discharged by means of a rotating sluice or may be spun off by centrifugal force by rapidly rotating the leaves. |

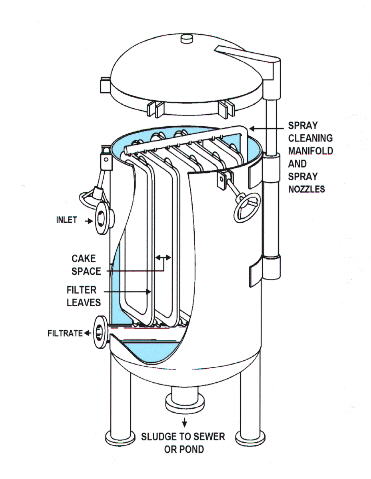

VERTICAL TANK - VERTICAL LEAF FILTER

|

This filter has small floor space requirements, but must have sufficient head room for removal of the leaves. It has a high ratio of filter area to filter shell volume. It can be made as a wet discharge sluicing filter (as shown) or as a dry cake discharge filter with leaf vibrators. |

FILTER PRESS

|

The filter press has numerous versions. The illustration shows one with caulked-in metal septa with recessed cake space. Other types have flush plates dressed with paper or cloth separated by open frames where the cake is formed. The presses may be automated. Some operate up to 250 psi (18 atm). The filter is used where dry cake discharge is required and in systems where no dangerous or toxic fumes exist. |

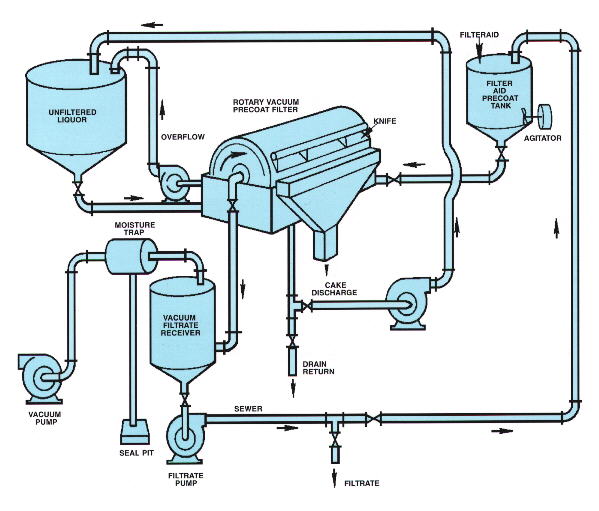

Rotary Vacuum Precoat

Rotary Vacuum Precoat Filters are typically used for thick, difficult to filter liquids or when the solids content is high. The precoat is formed on a drum with a cloth or metal-septum by recirculating a 2 - 5 % filter aid slurry. A 5 to 10 cm (2 - 4 inch) cake can be applied in an hour or less. Too rapid precoating rate and too high filter aid concentration can cause excessive cake cracking. The septum should be kept clean, as it can be a source of cake cracking and non-uniform thickness.

During the operating cycle, the process liquid passes through the cake leaving the solids on the precoat surface. A mechanically operated knife blade continuously shaves off the filterable solids and leaves a clean filtering surface. Selection of the proper depth of cut depends mostly on the nature and quantity of the solids. Cycle lengths vary from 8 to 24 hours typically, depending on depth of cut and cake thickness.

Flowrates are, for the most part, dictated by the filter aid solids and liquor viscosity. Common drum speeds range from 1 to 1/5 revolutions per minute. The optimum grade and type of filter aids is the grade which will maintain the solids on the surface of the cake. Optimum clarity occurs when solids are retained at the precoat surface. Best personnel are available to aid in this selection. Laboratory filtration's are a no risk method for investigating this and all other filtration variables.

|